How to recognise the Good, the Bad and the Ugly!

Skip to the bottom for the Special offer!

I recently had an opportunity to look over some tools from other providers in the market, and while it’s been a long time since I was employed in the General Engineering sector, some things remain constant, what is the best material for the task? Whether 3D Printing a toy car, building a Cubby House, machining or fabricating Coin Ring Tools. The question is fundamental!

The material selection and its suitability for the task impact the tool’s durability, service life, maintenance, price and efficiency. Or how well does it do the task for which it was designed?

The material selection and its suitability for the task impact the tool’s durability, service life, maintenance, price and efficiency. Or how well does it do the task for which it was designed?

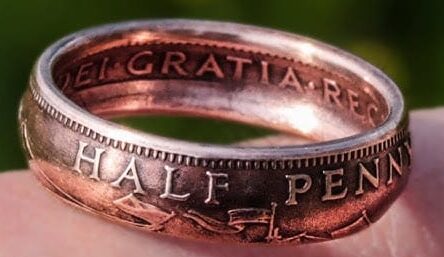

Sometimes it sounds right – tool steel? But when there are obvious scratches, dents and wear marks or a poor machine finish, you have reason to question the material in use. The old Castrol GTX “Oils Ain’t Oils” commercial from the 80s is a case in point. Choosing to use a low-quality material may reduce the price at a basic level, however, in coin ring making the lack of “finish” directly impacts the detail in the coin’s embossing.

The coin may have had fine

details, but the process has worn them away. Poor ring detail can be the fault of several factors, including coin selection or poor annealing practices. But as the by-line implies, “Oils Ain’t Oils

details, but the process has worn them away. Poor ring detail can be the fault of several factors, including coin selection or poor annealing practices. But as the by-line implies, “Oils Ain’t Oils

It’s tempting to show images of these cheaper tools, but it seems more appropriate to show the tools I used. These are the reduction dies, made from stainless tool steel, polished to the highest level. The feel in the hand is the first tell-tale and you see your image in the die wall is the other. I have a full set these days as it has added to the flexibility of the tool. The 2.5mm steps mean you can select the best size to suit the coin you plan to fold.

It’s tempting to show images of these cheaper tools, but it seems more appropriate to show the tools I used. These are the reduction dies, made from stainless tool steel, polished to the highest level. The feel in the hand is the first tell-tale and you see your image in the die wall is the other. I have a full set these days as it has added to the flexibility of the tool. The 2.5mm steps mean you can select the best size to suit the coin you plan to fold.

But I still struggled to get a good ring every time. Invariable the coin would move in punching. I had wobbly rings.  But it was a total game-changer was when I got the Auto-centring Coin Punch.

But it was a total game-changer was when I got the Auto-centring Coin Punch.

Without anything but the coin, you screw the two halves of the Zinc plated harden tool steel body together and the coin is held tight, insert the punch and “Willa” a perfectly centred hole every time.

The hollow ground punches cut your selected size perfectly. Bang in the middle every time!

I sold what bits I could and purchased the whole kit for myself. Yep! The Master Deluxe Kit. It’s got the lot! Jason calls it, the Whole Gamut!

This started out as a post about material selections for tools. But it is just that the right materials are used in the right place for the right tool. This means a tool set that will last a lifetime. I do not doubt that my son’s son could use these same tools one day. They are that good!

$2960.00